1. Project Background

Customer Requirements: A leading battery material manufacturer needs to build a smart high-density warehouse to meet the following requirements:

Storage Requirements: Over 2,000 SKUs (including lithium-ion battery separators, cathode materials, anode materials, and electrolytes), supporting mixed storage of film rolls (diameter 50-300 mm) and granular powders (such as silicon-carbon anodes);

Efficiency Targets: Average daily order processing of 15,000 orders, with a peak throughput of 30,000 items per day;

Compliance Requirements: Anti-static (surface resistance ≤ 1×10⁶Ω), moisture-proof (humidity ≤ 30%), and contamination-proof (cleanliness ISO Class 7), compliant with ISO 9001 and UL safety standards;

Cost Optimization: Reduce reliance on manual labor and lower the goods damage rate to below 0.1%.

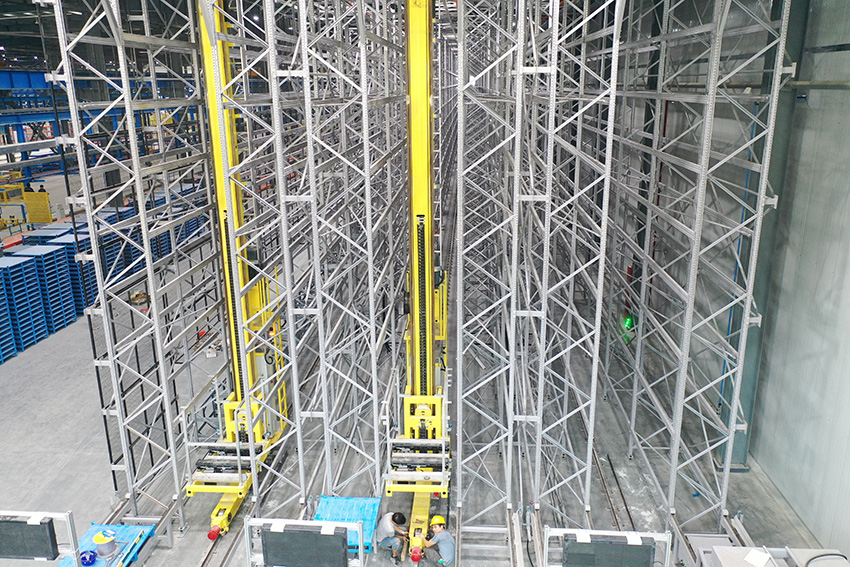

2. Technical Highlights

High-precision anti-contamination design:

The shuttle cart forks are equipped with a vacuum suction device (accuracy ±0.05 mm) for precise handling of film rolls and powder materials;

The shelf panels are coated with anti-static epoxy resin (surface resistance ≤1×10⁶Ω) to prevent static electricity from attracting dust.

Precise Environmental Control:

The temperature-controlled zone is equipped with an inert gas fire suppression system (heptane), with a response time of ≤30 seconds;

Humidity sensors are linked to dehumidification units, automatically activating desiccant regeneration when humidity exceeds limits.

Efficient sorting strategy:

WMS consolidates batches based on material usage (e.g.,集中分配隔膜+电解液 for lithium-ion battery module production orders), reducing shuttle cart idle rates;

AGVs operate in a multi-vehicle collaboration mode, improving cross-zone transportation efficiency by 50%.