1. Project Background

Customer Requirements: A car refrigerator manufacturer needed to build a smart logistics warehouse to meet the following requirements:

Storage Requirements: Over 2,000 SKUs (including car refrigerators of different sizes, accessories, and customized models), supporting constant temperature (10-15°C) storage;

Efficiency Targets: Average daily order processing of 6,000 orders, with a peak throughput of 15,000 boxes per day;

Compliance Requirements: Shock-resistant and moisture-proof design (to protect the precision components inside the car refrigerators), compliant with ISO 13485 medical device-grade quality standards;

Cost Optimization: Reduce reliance on manual labor and lower the goods damage rate to below 0.2%.

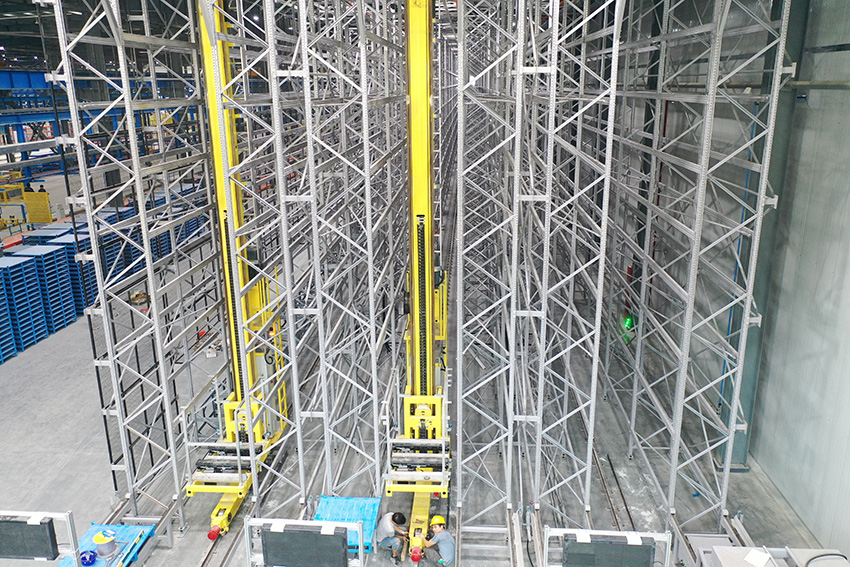

2. Technical Highlights

Customized Packaging Design:

Four-way shuttle cart forks equipped with adaptive clamps (width 0.8m–1.5m), compatible with cylindrical and square containers;

Shelf panels feature anti-slip silicone pads + elastic limiters to prevent refrigerator movement.

Precise Temperature Control Management:

Constant-temperature zone shelves independently equipped with refrigeration units, temperature fluctuation ≤ ±0.5°C;

The refrigeration zone employs cascade refrigeration technology, supporting multi-temperature storage from -5°C to 15°C.

Efficient Sorting Strategy:

WMS consolidates order batches by product category (e.g., vehicle refrigerators + accessories combined orders) to reduce shuttle cart movement frequency;

AGVs operate in relay mode, improving cross-zone transportation efficiency by 50%.