1. Project Background

Customer Requirements: A large chemical company needs to build a smart Automated Storage and Retrieval System to meet the following requirements:

Storage Requirements: Over 2,000 SKUs (including flammable liquids, corrosive solids, oxidizers, etc.), supporting mixed storage of drum-packed, bottle-packed, and bulk goods;

Safety Requirements: Explosion-proof and fire-resistant (compliant with OSHA 1910.106 standards), leak-proof (negative pressure sealed design), independent temperature and humidity control (temperature ≤30°C, humidity ≤60%);

Efficiency targets: Average daily order processing of 8,000 orders, peak throughput of 20,000 tons per day;

Compliance requirements: Full traceability (batch error ≤0.01%), compliant with GHS (Globally Harmonized System of Classification and Labelling of Chemicals).

2. Technical Highlights

Hazardous Chemical Safety Control:

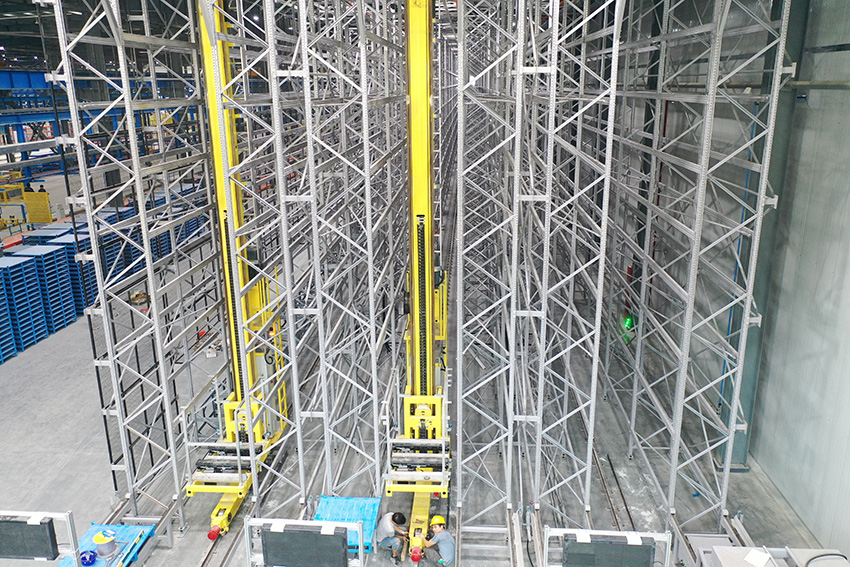

The explosion-proof stacker crane uses flame-retardant cables + explosion-proof motors (compliant with ATEX/IECEx standards), with a chassis grounding resistance ≤4Ω;

Leak-proof trays with built-in drainage channels and absorbent cotton automatically collect leaked liquids into emergency storage tanks.

Precise Environmental Control:

The temperature-controlled zone is equipped with an inert gas fire suppression system (heptane), with a response time ≤30 seconds;

Shelf panels are coated with corrosion-resistant materials (e.g., polytetrafluoroethylene), with acid and alkali corrosion resistance rated at ≥Class F.

Efficient Sorting Strategy:

The WMS consolidates batches based on chemical hazard levels (e.g., separating flammable materials from oxidizers during sorting) to reduce AGV path conflicts;

AGVs operate in a multi-machine collaboration mode, improving cross-zone transportation efficiency by 50%.