1. Project Background

Customer Requirements: A cross-border logistics company needs to build a smart high-density warehouse to meet the following requirements:

Storage Requirements: Over 10,000 SKUs (including small cross-border e-commerce items, bulk commodities, and hazardous materials), supporting mixed storage of cardboard boxes, wooden boxes, and pallets;

Efficiency Goals: Average daily order processing of 50,000 orders, with a peak throughput of 100,000 items per day;

Compliance Requirements: Multi-country customs labels (e.g., EU CE, US FDA), temperature and humidity control (15-25°C), shock and moisture resistance (humidity ≤50%), compliant with ISO 9001 and WTO trade facilitation standards;

Cost Optimization: Reduce reliance on manual labor and lower goods damage rate to below 0.1%.

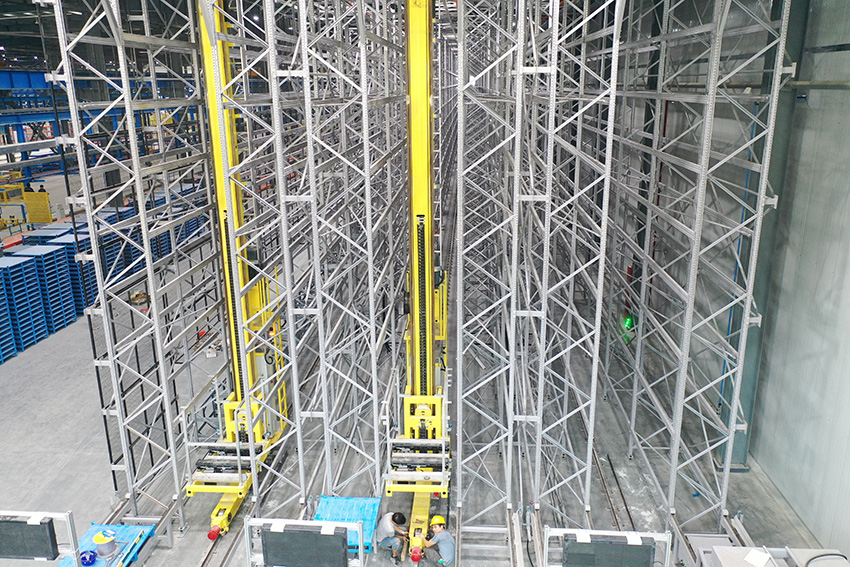

2. Technical Highlights

Multi-country cargo adaptation design:

Four-way shuttle truck forks are equipped with multi-language label scanners (supporting 10 languages including Chinese, English, German, and Japanese), with a scanning response time of <0.1 seconds;

Shelf panels use a modular design (width 50 mm-1.2 m) to accommodate different sizes of cardboard boxes, wooden boxes, and pallets.

Smart Compliance Management:

The WMS integrates a multi-country customs database (e.g., HS codes, tax rates), automatically matches declaration forms, and generates electronic customs seals;

Hazardous material zones are equipped with gas leak detectors, triggering automatic sprinkler activation and alarms in case of abnormalities.

Efficient Sorting Strategies:

The WMS consolidates order batches by destination country (e.g.,集中 distribution of North American orders), reducing four-way shuttle cart cross-zone paths;

AGVs operate in relay mode, improving cross-zone transportation efficiency by 50%.