1. Project BackgroundClient Requirements: A well-known home appliance company needs to build an intelligent three-dimensional warehouse to meet the following requirements:

Storage Requirements: Over 3000 SKUs (including refrigerators, washing machines, air conditioners, and small appliances), supporting storage of whole machines (maximum dimensions 2.4m × 1.8m × 1.5m, weight 1-5 tons) and spare parts;

Efficiency Goals: Average daily processing of 12,000 orders, peak throughput of 30,000 tons/day;

Compliance Requirements: Seismic and moisture-proof design (such as waterproofing for air conditioner compressors), compliance with ISO 9001 quality management system;

Cost Optimization: Reduce reliance on manual labor and decrease cargo damage rate to below 0.5%.

2. Technical Highlights

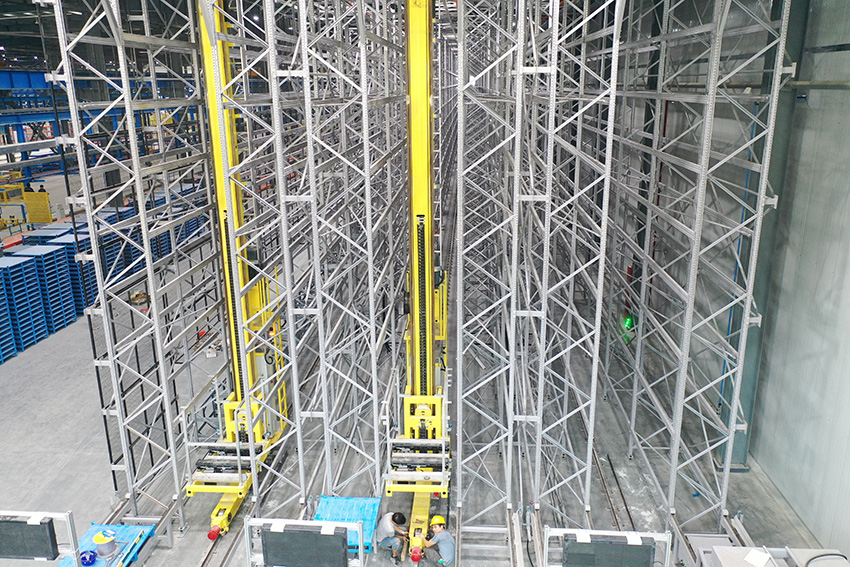

Large Appliance Compatibility Design:

The forks of the stacker crane are equipped with hydraulic lifting buffer devices, capable of bearing loads up to 5 tons, with vibration sensors monitoring the handling process in real time;

The storage area shelves of the entire machine are made of thickened steel plates (thickness ≥12mm), with each shelf capable of bearing loads ≥3 tons.

Anti-Vibration and Moisture-Proof Technology:

The storage areas for air conditioners and washing machines are equipped with dehumidification systems (humidity controlled between 40% and 60%);

The compressor areas of refrigerators are fitted with anti-vibration brackets (using elastic damping materials).

Efficient Sorting Strategy:

The WMS merges order categories into batches (e.g., refrigerator + washing machine combination orders) to reduce the number of stacker crane movements;

AGVs use a relay mode, improving cross-zone transportation efficiency by 40%.