1. Project Background

Customer Requirements: A well-known lighting company needed to build an automated Automated Storage and Retrieval System to meet the following requirements:

Storage Requirements: Over 5,000 SKUs (including ceiling lights, downlights, decorative lights, etc.), supporting irregular packaging such as cardboard boxes, wooden boxes, and glass covers;

Efficiency Goals: Average daily order processing of 8,000 orders, with a peak throughput of 20,000 boxes per day;

Compliance Requirements: Earthquake-resistant and moisture-proof design (as lighting fixtures are fragile), compliant with the ISO 9001 quality management system;

Cost Optimization: Reduce reliance on manual labor and lower the goods damage rate to below 0.3%.

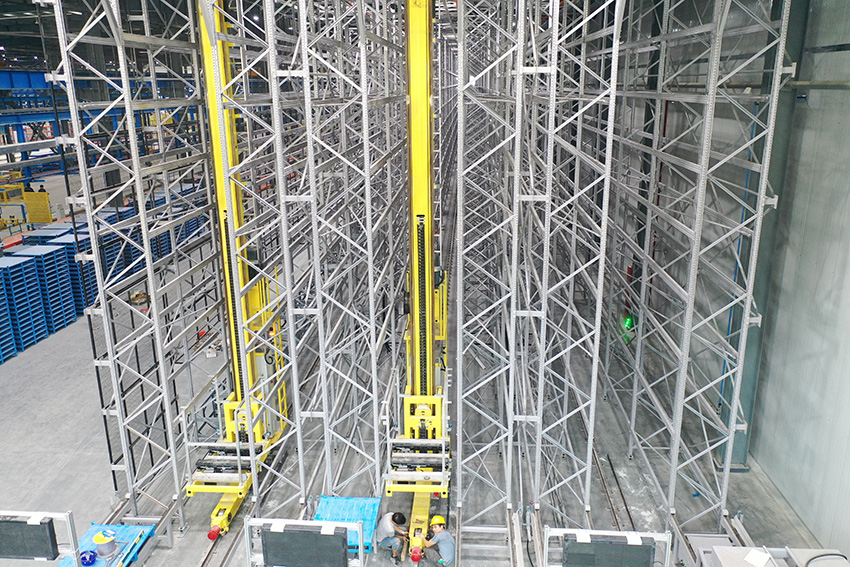

2. Technical Highlights

Fragile Item Protection Design:

Silicone buffer pads are added to the forks of the stacker crane, and vibration sensors monitor the handling process in real time.

Glass cover lamps are stored separately on shock-resistant shelves (honeycomb cardboard layers + spring dampers).

High SKU Management:

RFID tags are embedded in the smallest packaging units of lighting fixtures, with a scanning response time of <0.1 seconds;

The WMS categorizes storage based on lighting fixture attributes (color temperature, power), enabling rapid matching of order requirements.

Energy Saving and Consumption Reduction:

The stacker crane uses variable-frequency motors, reducing standby power consumption by 50%;

LED energy-saving light strips are installed on the warehouse ceiling, with light uniformity ≥80%.