Customer Requirements: A multinational medical device company needs to build a smart warehouse to meet the following requirements:

Storage Requirements: Support storage of all types of products, including sterile medical devices, high-value consumables, and implants, with temperature and humidity zones (2-8°C refrigeration, 15-25°C ambient temperature, -20°C freezing);

Traceability Accuracy: Full traceability throughout the process, with batch error ≤0.01%, and support for UDI (Unique Device Identification) management;

Efficiency Goals: Average daily order processing of 15,000 orders, with a peak throughput of 30,000 boxes per day;

Compliance Requirements: Compliance with GMP, GDP, and ISO 13485 certifications, with a cleanroom grade of ISO Class 5 in the sterile zone.

1. Inbound Process

Receiving Inspection: AGVs transport medical devices from the loading dock to the quality inspection area, where AI vision systems inspect packaging integrity and UDI code compliance;

Sterilization: High-value consumables enter an ISO Class 5 cleanroom, where robotic arms perform sterilization and packaging;

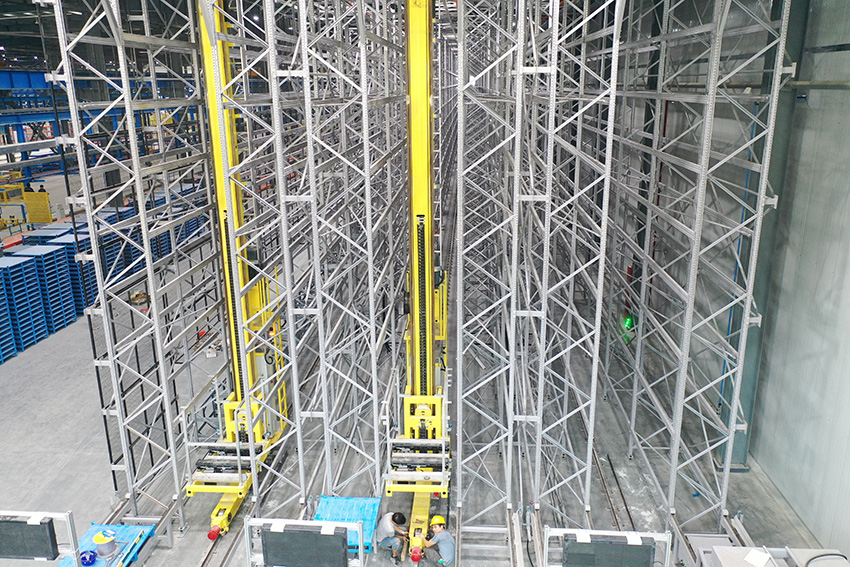

Shelf Storage: CTU robots sort by temperature zone and stack medical devices into designated storage locations in the automated storage system (e.g., frozen orthopedic implants).

2. Outbound Process

Order Picking: WMS generates batches based on surgical schedules, and CTU robots precisely pick medical devices across temperature zones (e.g., room-temperature surgical forceps + refrigerated hemostatic gauze);

Consolidation and verification: AGVs transport instruments to the consolidation area, where robotic arms perform box-level verification (scanning + weight verification);

Loading and outbound: Refrigerated instruments are transported directly to cold chain transport vehicles by sealed AGVs, with onboard IoT devices monitoring temperature and humidity during transit.