1. Project Background

Customer Requirements: A well-known motorcycle manufacturer needs to build a smart Automated Storage and Retrieval System to meet the following requirements:

Storage Requirements: Over 2,000 SKUs (including complete vehicles, engines, and spare parts), supporting storage of gasoline-powered vehicles (dimensions 2.5m×1.5m×1.2m, weight 150-300kg) and electric vehicles (including battery packs);

Efficiency Goals: Average daily order processing of 12,000 orders, with a peak throughput of 30,000 units per day;

Compliance Requirements: Explosion-proof and fire-resistant design for the fuel zone (compliant with GB 50058 standards), static-proof design for the battery zone (compliant with UN38.3 standards), and integrated fire protection systems throughout the facility;

Cost Optimization: Reduce reliance on manual labor and lower the goods damage rate to below 0.3%.

2. Technical Highlights

Fuel Safety Management:

Explosion-proof storage areas are protected by inert gas (oxygen concentration ≤ 1%), with combustible gas detectors and automatic sprinkler systems embedded in the shelves;

Fuel tank pallets are equipped with leak detection modules to monitor fuel penetration risks in real time.

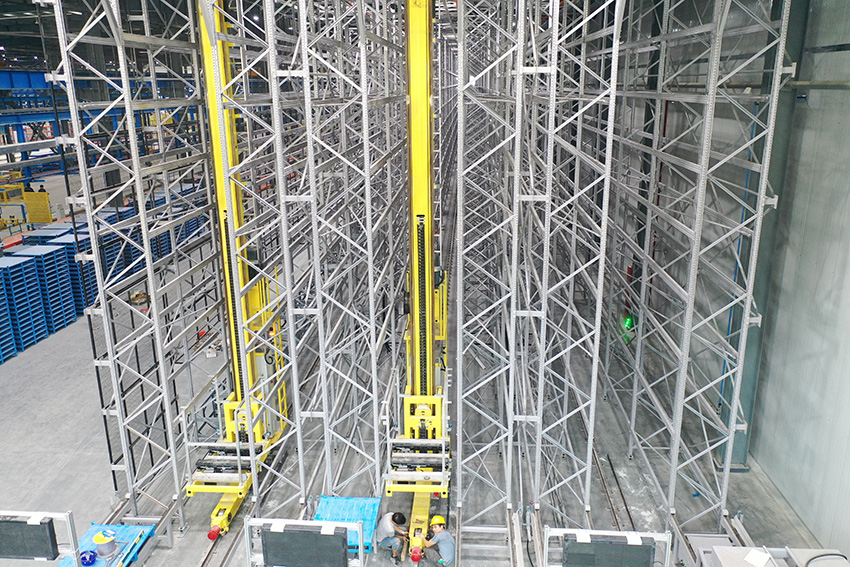

Large Item Handling Adaptation:

Stacker forks are fitted with hydraulic lifting buffer devices, capable of handling loads up to 3 tons, with vibration sensors monitoring the handling process in real time;

Shelf panels in the whole-vehicle storage area use anti-slip silicone pads + elastic limiters to prevent vehicle slippage.

Efficient sorting strategy:

WMS consolidates order batches by vehicle type (e.g., motorcycle + accessories combination orders) to reduce the number of shuttle movements;

AGVs use a relay mode, improving cross-zone transportation efficiency by 40%.