Customer Requirements: A large pharmaceutical group needs to build smart logistics centers in key hub cities across the country to meet the following requirements:

Storage Capacity: Support multi-temperature storage, including ambient temperature (15-25°C), cool temperature (≤20°C), refrigerated temperature (2-8°C), and frozen temperature (-25°C);

Inventory turnover: Process an average of 20,000 orders per day, with a peak throughput of 50,000 boxes per day;

Compliance requirements: Meet GSP certification standards, with continuous temperature and humidity monitoring, and medication traceability accuracy of ≤0.01%;

Cost optimization: Reduce reliance on manual labor and minimize medication expiration losses (target ≤0.5%).

Dynamic allocation of storage strategies (such as ABC classification + expiration date priority), automatically avoiding the accumulation of near-expiration drugs;

Real-time interaction with ERP and TMS systems to generate optimal picking paths.

WCS (Warehouse Control System):

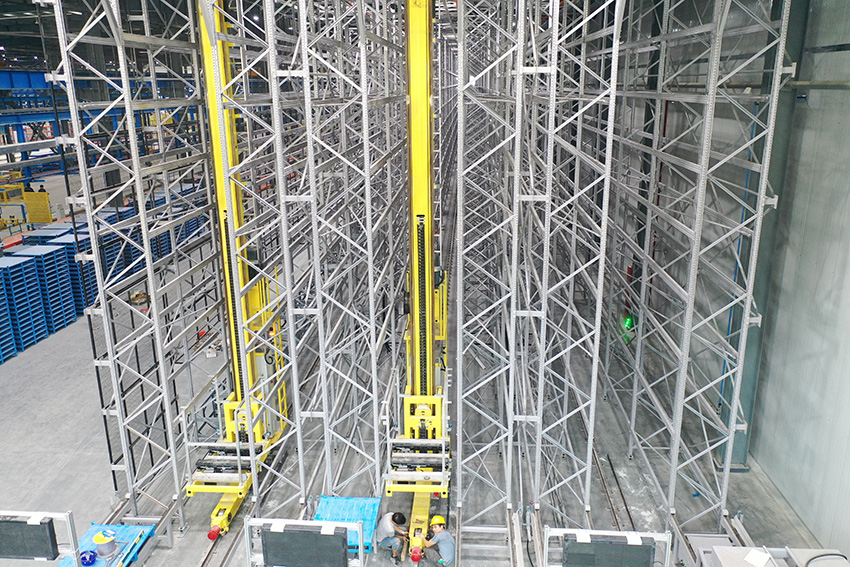

Coordinate the collaborative operation of four-way shuttle carts, AGVs, and sorters, with dynamic adjustment of task priorities;

Equipment fault self-diagnosis, with redundant backup to ensure 24/7 operation.