1. Project Background

Customer Requirements: A well-known tire manufacturer needed to build a smart Automated Storage and Retrieval System to meet the following requirements:

Storage Requirements: Over 3,000 SKUs (including passenger car tires, commercial vehicle tires, engineering tires, and accessories), supporting the storage of special tires such as all-steel radial tires (weighing 50-500 kg) and winter tires;

Efficiency Goals: Average daily order processing of 12,000 orders, with a peak throughput of 30,000 items per day;

Compliance Requirements: Anti-aging (temperature and humidity control), fireproof and explosion-proof (rubber is flammable), compliant with the ISO 9001 quality management system;

Cost Optimization: Reduce reliance on manual labor and lower the goods damage rate to below 0.3%.

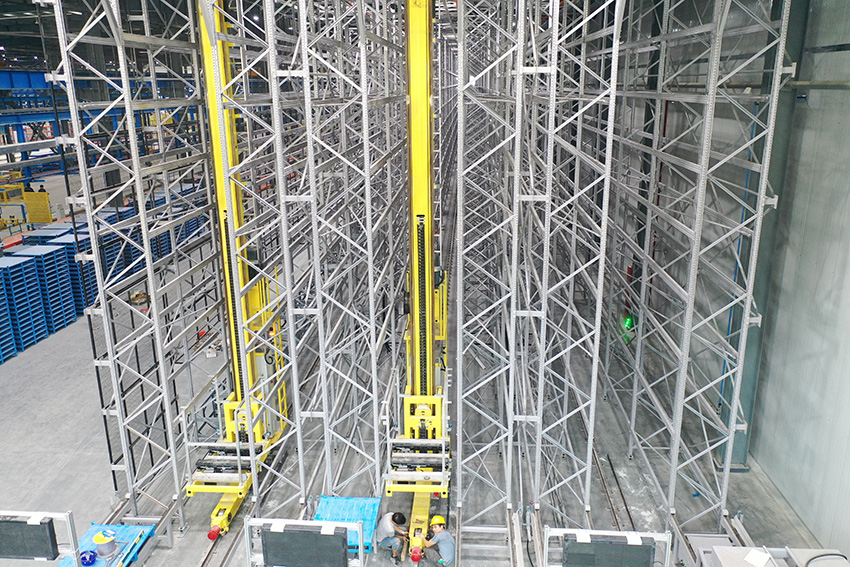

2. Technical Highlights

Tire Protection Design:

Silicone buffer pads are installed on the forks of the stacker crane, with a load capacity of up to 5 tons, and vibration sensors monitor the handling process in real time.

The shelf panels are equipped with anti-slip rubber pads and elastic limiters to prevent tire slippage.

Precise Temperature and Humidity Control:

The shelves in the constant temperature zone are independently equipped with refrigeration units, with temperature fluctuations of ≤±0.5℃.

The general tire zone uses natural cooling sources (NH3 cascade refrigeration), reducing energy consumption by 30%.

Efficient Sorting Strategy:

The WMS consolidates order batches based on vehicle type (e.g., sedan + SUV tire combination orders) to reduce the number of shuttle movements;

AGVs operate in relay mode, improving cross-zone transportation efficiency by 40%.