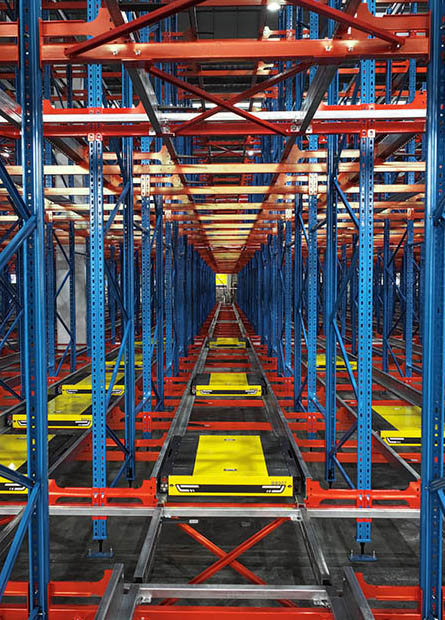

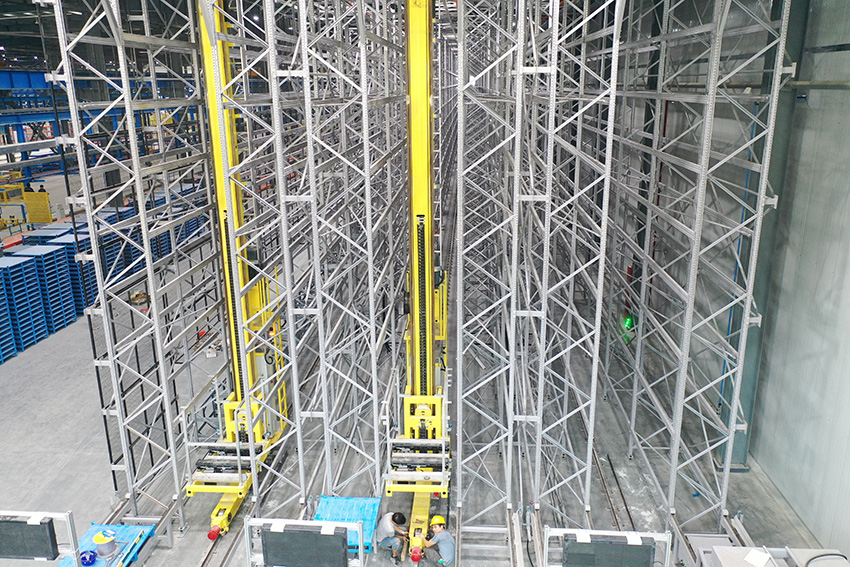

The four-way shuttle automated warehouse system has become one of the mainstream choices for modern intelligent warehousing due to its high-density storage, high automation, intelligent flexibility, safety and reliability, and excellent scalability. It excels in enhancing space utilization, operational efficiency, and reducing labor costs.

If you are considering deploying such a system, it is recommended to conduct a comprehensive evaluation based on the following aspects:

Business Requirements and Scenarios: Define your storage capacity needs, goods types, inbound/outbound frequency, projected future business growth, and any special environmental requirements (e.g., cold chain).

Technical Compatibility: Evaluate the manufacturer’s technical capabilities, performance parameters of core equipment (shuttles, lifts) such as load capacity, speed, and precision, the intelligence level of the software system (WMS/WCS functionality, digital twin support), and integration capabilities with existing systems.

Investment and Return: Balance initial capital expenditure against long-term operational costs (power consumption, maintenance) and anticipated benefits (efficiency gains, labor savings, error reduction).

Supplier Selection: Evaluate the manufacturer’s technical expertise, industry experience, successful case studies, and after-sales service capabilities.