1. Project Background

Customer Requirements: A wind power equipment manufacturer needs to build a smart Automated Stacking Warehouse to meet the following requirements:

Storage Requirements: Over 800 SKUs (including blades, gearboxes, generators, and towers), supporting the storage of oversized components such as blades (length 50-100m, weight 5-20 tons) and gearboxes (weight 10-30 tons);

Efficiency Targets: Average daily order processing of 2,000 orders, with a peak throughput capacity of 50,000 tons per day;

Compliance Requirements: Rust and corrosion prevention (humidity ≤40%, surface coating protection), fire and explosion prevention (electrical components isolated), compliant with ISO 9001 and IEC 61400 standards;

Cost Optimization: Reduce reliance on manual labor and lower cargo damage rate to below 0.1%.

2. Technical Highlights

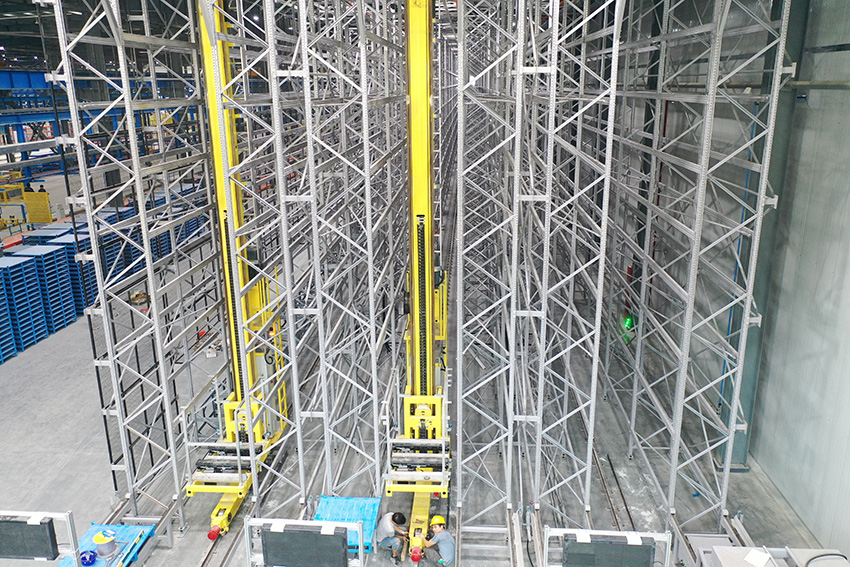

Extra-large component adaptation design:

The stacker forks use a box-type steel structure (thickness ≥ 25 mm) with a load capacity of up to 20 tons, and anti-vibration sensors monitor the handling process in real time.

Anti-slip rubber pads and elastic limiters are added to the blade shelf panels to prevent the blades from sliding.

Corrosion Prevention and Control:

The temperature-controlled zone is equipped with an inert gas fire suppression system (heptane), with a response time of ≤30 seconds;

Anti-static shelves (surface resistance ≤ 1×10⁶Ω) prevent static electricity from attracting dust to metal components.

Efficient Sorting Strategy:

WMS consolidates batches by operational area (e.g., orders combining blades and gearboxes from a specific wind farm), reducing the number of stacker crane movements;

AGVs operate in a multi-machine collaboration mode, improving cross-zone transportation efficiency by 50%.